Part 1 - Grandad's House - Isle of Wight

In the summer of 2013 we made the journey down to the Isle of Wight to visit Grandad, to trim the long branches of his apple tree and to take away as many apples as we could carry.

Not shown, Annliz, who took all the photos.

Tree inspection

Matt up ladder

Matt high up

Ian with spiky pole

Grandad overseer

Ladder stability

Press (car jack) installed

Press installed 2

Press closeup

An entire bucket full of apples. It's about 5 gallons, but inefficiently packed.

Full apple bucket

Normally some sort of porous muslin would be used here. We had some offcuts from our net curtains. It seemed to work fine. A washing up bowl will catch the juice.

Pressing apples

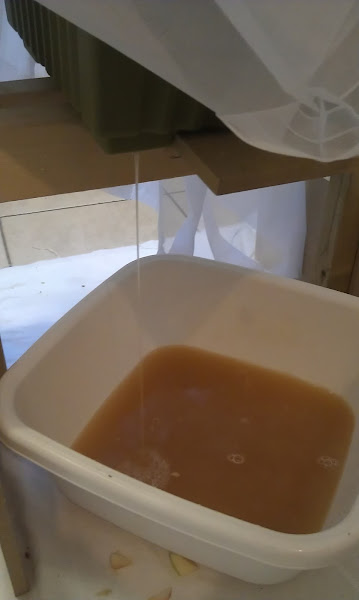

We have apple juice! Very dark and murky, but it's 100% grandad's apples. The press allows a pretty slow but constant stream of apple juice.

Apple juice collection bucket (washing up bowl)

Apple juice 2

Fermenting kit

Fermenting stack

Clean bottles

Full bottles

Full bottles flash

Full bottles flash 2

Full bottles, no flash 2

2l bottle

2 2l bottles

4 bottles

Matt spent most his time up the tree.

It wasn't the longest ladder, so he had to do some climbing.

Luckily he doesn't mind hights.

We had a system, Matt would chop branches and Ian would pull them down into a pile with a spiky pole.

Always worth another pair of eyes to check nothing's going wrong.

The ladder wasn't as stable as this photo shows, even with multiple people to hold it.

Part 2 - Making the Press

This required multiple trips to Homebase, and a serious rummage through the spare room to find all the tools I half remembered owning.

Anthony supplied his beer making kit we bought from Wilkinson's the previous year. That shop is brilliant for cheap brewing stuff.

This was a much planning as we managed before diving into the project. A few crude scribbles as a rough attempt to decide how much wood we needed to buy.

Plan

Complete frame

Frame + Matt

Corner + bolt

Frame + mess room

Frame + bucket

Matt measuring

Matt measuring, wide

Mask and hoover

Frame again

Matt and Ian sawing

Matt and Ant sawing

Ant and Matt drilling

Frame with legs, Matt

Ant apple chopping

More chopping

Apple bucket

Matt fixing platform to the frame

A tired Annliz arrived home to all the chaos and mess.

A few cuts with the hand saw, a few drill holes, 4 bolts and we have the basic frame!

The living room had loads of old curtains over everything to catch sawdust.

A closeup of the corner joint and single bolt. This design has the bonus feature of being able to fold almost flat for storage.

Pretty proud of our progress so far. Tools everywhere, loads of mess, all good things.

The container chosen to hold the smashed up apples - a plant pot with two holes drilled into the bottom.

Measuring the MDF for the feet and the bucket's platform.

Measure twice, cut once.

MDF makes loads of dust when you cut it with a fret saw, and the dust is pretty horrible if you breathe it in. So, masks and goggles. We'd have felt pretty stupid if we had an accident with safety equipment sat in the box next to us.

Also, we had the idea to vacuum up the dust straight from the blade while cutting, so one person held the nozzle up to the saw while the other one cut. Almost no dust in the air, or on the floor!

The bucket now has a small bracket to hold it steady in the frame.

The sawing/ hoovering combo.

Ant arrived after he finished work, to help out and see what was going to happen to his brewing equipment.

These are the feet nearly finished, with guide holes for screws.

Now the frame is freestanding, and has a bracket to hold the bucket in place.

Part 3 - Crushing apples

The same day, we started cutting up the apples, to give our press a chance at crushing them. In accurate technical measuring terminology, we had one large suitcase of apples to squeeze.

Chopped apples in bucket

Ant had the exciting job of slicing a few hundred apples into rough quarters.

It took a while. The fish watched.

Apple chunks cut a bit smaller.

Another bracket was needed to hold the top of the car jack in place.

Press (car jack) installed

This angle shows the internal plate and rod which will spread the force evenly over the apple chunks.

The choice of press wasn't ideal, as its triangular shape doesn't easily push straight down into the bucket. The extra brackets help a bit.

Full apple bucket

Pressing apples

Apple juice collection bucket (washing up bowl)

We have no idea how much juice to expect. How many washing up bowls does a suitcase of apples make??

Part 4 - Bottling the Cider

The bowl of juice was poured into this plastic keg and some beer making yeast was thrown in. The size of the keg was complete overkill, the juice barely reached the tap. We left it raised above the ground to aid the syphoning off afterwards. It was left to ferment for about 6 weeks.

At about this point, I measured the specific gravity of the juice, to find out how much sugar was in the solution. Like a salty solution, things float higher in the water when sugar is present. Once the yeast converts all the sugar into alcohol, the float sinks further into the solution. The difference between the two levels shows how much sugar was converted, and so the amount of alcohol can be calculated.

Fermenting kit

The aim was to keep the barrel as stationary as possible, so the sediment would sink to the bottom. It was important to avoid touching anything as much as possible.

The pipes and bottles had to be cleaned thoroughly. I also heated them in the oven to ensure anything was killed off.

It was impossible to take photos of syphoning the cider out of the barrel while doing it. Care was taken to avoid disturbing the sediment layer at the bottom. Syphoning is tricky, but doesn't taste bad if you get it wrong while sucking the cider down the tubes.

The fancy bottles were filled first. One each for Matt and Ian.

It's amazing how clear the cider went! No cloudy farmhouse scrumpy here, it's bright yellow and shines brilliantly.

Very very happy with how it looks.

It looks just as good in regular light.

I added a bit of extra sugar to the second bottle, in an attempt to get some secondary fermentation going. In theory it would add more CO2 to the solution and would potentially end up fizzy. In practice it made a slight pop noise when opened two weeks later, but it wasn't sparkling.

There is still plenty of cider in the barrel, so a less fancy bottle is filled with the remains. Still clear and a great colour.

Another large bottle is almost filled, before the dregs from the barrel start to stir up the sediment. This bottle was a bit cloudy as a result, but it's not terrible.

The completed batch. It turns out one suitcase of apples makes 3/4 of a washing up bowl of apple juice, which makes almost 6L of cider.

Using the measures of specific gravity taken before the fermentation happened, it was possible to calculate an approximate alcohol strength for the cider. Using dodgy measuring and even more dodgy maths, I think we managed between 6-7%, which makes sense bearing in mind we used yeast typically used for beer making. We can be pretty happy with that!

The end result!!